This tutorial on fiber optic safety is in two parts - construction and fiber installation.

Safety in the lab or on the job site must be the number one concern of everyone. Besides the usual safety issues for construction, generally covered under OSHA rules (OSHA 10 and 30), fiber optics adds concerns for eye safety, chemicals, sparks from fusion splicing, disposal of fiber shards and more. Before beginning any installation, safety rules should be posted on the classroom wall, lab wall or on the job site and reviewed with all onsite personnel. All personnel must wear the usual construction safety gear plus everyone must wear eye protection whenever working with fiber.

Eye Safety

Many people are concerned that the most dangerous part of fiber optic work was the chance you might get your eyeballs burned out by laser light in the fiber. They had confused optical fibers to the output of high powered lasers used in labs. Or perhaps they had been going to the doctor to get warts burned off their skin using lasers with fiber optic probes or even seen too many science fiction movies.

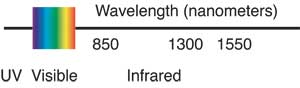

Light In Most Fiber Optic Networks Is Invisible To The Human Eye

First, there is an issue of wavelength. Your eye cannot see many of the wavelengths used in fiber optics because the eye is sensitive to light in the blue to red region of the spectrum while fiber optic systems operate in the infrared. If there is dangerous levels of power in a fiber, you cannot see it in time to avoid it; you must test for power with a power meter or some some device that measures infrared light or converts it to visible light. The liquid in your eye which is mostly water, which absorbs light in the infrared heavily. Light from most fiber optic sources will be absorbed by this liquid, so any potential harm is likely to come to the lens or cornea, not the retina.

Power In Fiber Optic Networks

Most fiber optic systems communications do not have sufficient power to cause harm to your eyes and the light coming out of a fiber is expanding so the farther you are away from the end of the fiber, the lower the exposure. Having said that, consider yourself warned. In more recent times, some fiber optic systems are carrying sufficient power to be dangerous and some fiber optic inspection techniques increase the chance of harm (see below) . Let�s look at the issues.

The key to understanding the power issue is understanding power levels, wavelength of the light and the nature of light transmission in optical fiber.

Fiber optic medical laser systems used for surgery and laser machining systems certainly have enough power to cause harm to your eyes, as well as burn off warts or machine some types of materials. Those systems use very high power lasers, often CO2 lasers, which emit radiation at a wavelength that is really heat not light, around 10 microns wavelength. This wavelength is readily absorbed by materials and can heat them quickly, cutting those materials easily.

In medical applications, the heat not only cuts tissue, but it cauterizes, stopping bleeding, a major advantage. It also cuts more precisely with a small focused spot, allowing more exacting work to be done.

Laser machining also takes advantage of the smaller focused spot of the laser, making it possible to create smaller holes or parts more precisely than conventional machining. The smaller spot size also reduces local heating, reducing the need for cooling and preventing thin materials from warping.

Some of these high power systems use fiber with focusing lenses on the end for delivery, allowing use of a flexible probe that increases the flexibility of the machine�s use. However, the power is so high that any dust or dirt on the end of the fiber may be vaporized, causing damage to the end of the fiber probe.

Fiber optic communications systems use much less power. First of all, most sources used in fiber optics are optimized for modulation speed, not absolute power. In fact, in most telephone links, the laser has too much power, so much it needs an attenuator at the receiver to prevent overloading. Secondly, it you put too much power in a fiber, it creates some types of secondary light emission that can add to the noise in the system, causing problems.

Premises cabling with multimode fiber and LED sources has very low power levels, too low to be a hazard. Higher speed premises links use VCSEL lasers, which are still quite low in power levels, and generally harmless.

Safety In High Power OSP Links

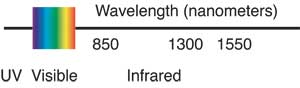

Two types of links have high power, as much as 100 times more than other communications systems, and they are CATV or video links at 1550 nm and telco long distance links using dense wavelength division multiplexing (DWDM.) The CATV or video links used in fiber to the home (FTTH - read more) may use fiber amplifiers (read more) that boost the power to very high levels, potentially dangerous the eye. Telco DWDM links are used on extremely long distance links (read more). They not only use fiber amplifiers for boosting the power, but they have many different signals operating at different wavelengths carried in one singlemode fiber. Any one wavelength may not be a problem, but the sum of 16, 32 or 64 individual wavelengths can be very powerful.

WDM (wavelength division multiplexing) networks have many wavelengths of light and the total power in the fiber is the sum of all the power from all the wavelengths.

Fiber amplifiers used in many WDM networks can increase the power by 20 dB - 100 times - or more.

Is it safe for fiber techs repairing cut fiber optic cables to splice OSP networks that use fiber amplifiers as repeaters? The answer is not a simple yes/no! The short answer is YES; the long answer is more technical and includes details that every OSP tech needs to know.

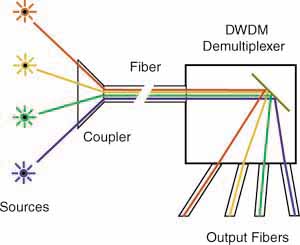

Fiber amplifiers have been around for decades, replacing electronic repeaters that convert a signal from the optical domain back into the electrical domain, remove some noise and retransmit it as an optical signal. Fiber amps replaced them because they used too much power and were unreliable. Fiber amplifiers are used in WDM systems where there can be power from a number of different wavelengths, increasing the total power, or in analog systems like CATV HFC systems where high power DFB lasers are used.

The most common fiber amp (EDFA - erbiun-doped fiber amplifier) uses some complex physics that allows light entering a special fiber (generally erbium-doped fiber) to be amplified by the light from a high power "pump laser" at a different wavelength (980 or 1480 nm). Pump lasers can be as powerful as 10 watts, +40 dBm! Fiber amplifiers have gains of around 20 dB, so a "0 dBm" laser (1 mw) input will be amplified to +20 dBm (100 mw). That is a LOT of optical power.

A second type of fiber amp (RAMAN) uses the transmission fiber to amplify the signal using high-power pump lasers, sometimes at both ends of the fiber, at particular wavelengths. These are less common.

The problem that field techs need to worry about is whether a fiber amp will shut down if the link is broken. Transmission equipment generally shuts down the transceiver if the receive sees no input and initiates an alarm. If there are fiber amps in the link, will they shut down if there is no input? The answer is maybe.

The problem seems to be a lack of standardization in fiber amp design. Some amps have sensors on the input that shuts down the pump laser when there is no input. Those should be safe. But most designs, it seems, do not have that feature. We talked to two manufacturers and two users and the consensus is that fiber amps will have the output of the pump laser on the output fiber even with no signal at the input.

One user tested a unit with an input sensor. With a range of inputs from -12 to -4 dBm, the output was a constant at around +20 dBm. Below, -12 dBm, the output was zero - no light at all - even though the EDFA was switched on. However, when the EDFA was switched off, the unit was simply a passive component and would transmit signals at 1490 nm but not at 1550 nm, probably due to a WDM component in the output.

We talked to a manufacturer who mentioned that some EDFAs are designed this way and some are just amps. For example, he told me their products will produce ~20 dB gain, so an input of 1 mw will yield ~100 mw output. But if you remove the input, the amp will amplify the noise and transmit the pump laser on the output which will be about 30 mw, with the bulk of the power in the pump laser wavelength. A WDM will filter out the pump laser, but if a tech looks at a broken fiber with this fiber amp as an input, he will still be looking at a 30 mw optical output.

It appears that the fiber tech doing restoration on broken OSP fibers needs to have assurance that either the network does not have any fiber amps in the link being repaired or the network has been completely powered down - including the amps.

Focusing Light Into The Eye Can Be Dangerous

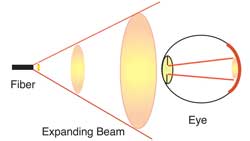

The next issue is focusing the light from a fiber into your eye. Light exiting an optical fiber spreads out in a cone, the angle of which is determined by the transmission characteristics of the fiber as defined by the numerical aperture. As your eye is further from the end of the fiber, the amount of radiation it receives is inversely proportional to the square of the distance � double the distance and cut the power by 1/4, ten times the distance reduces the power to about 1%. You do not have to be far away from the fiber for the power to be reduced to low levels.

Because the light is exiting the fiber in a cone-shaped beam, your eye cannot focus it on the retina. This is unlike the typical lab laser or laser pointer that shines a narrow, collimated beam that does not spread out; a beam your eye can easily focus on the retina, causing temporary blindness.

Finally, there is an issue of wavelength. Your eye cannot see many of the wavelengths used in fiber optics because the eye is sensitive to light in the blue to red region of the spectrum while fiber optic systems operate in the infrared. The liquid in your eye which is mostly water, which absorbs light in the infrared heavily. Light from most fiber optic sources will be absorbed by this liquid, so any potential harm is likely to come to the lens or cornea, not the retina.

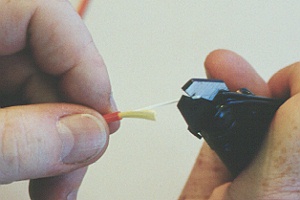

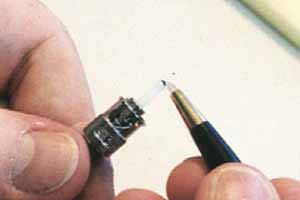

While the expanding beam of the light exiting the fiber makes it less of an issue for direct viewing, using a fiber inspection microscope can be a problem. We�ve tested this hypothesis ourselves, and can confirm that a microscope will focus virtually all the light back into the eye. Many microscopes used in fiber optics, therefore, have filters to absorb any infrared (IR) light that could be harmful. Be wary of inexpensive microscopes like the one shown, however, which may not have IR blocking filters.

To be certain fibers are safe to inspect or work with, always check fibers in an operating network with a fiber optic power meter to ensure no light is present before inspecting any connector with a microscope.

Hint: The camera in many early cell phones is sensitive to light in the infrared. So if you think a fiber has light being transmitted through it, use an old cell phone to take a picture of it. But try your cell phone first - here are photos of a test source taken with an older Motorola Razor phone from the early 2000s. Here is a video showing how it works.

So to sum up what we have said: 1) Most fiber optic links are harmless to eyes 2) Some links may be harmful, however, 3)Never take a chance � check the link before inspecting it!

Bare Fiber Safety

Fiber optics installation, however, is not without risks. The more common problem is getting scraps of fiber in your eye when working with fiber. While few fiber optic systems have harmful levels of power, every termination and splice produces shards (scraps) of optical fiber which is potentially very harmful to your eyes and skin or may stick in your clothing and be carried to other locations where it may be harmful to others.

These shards of fiber are tiny, thin and often very sharp where they broke off the fiber. They can easily puncture your skin, burying themselves deep enough to be difficult to pull out, if only you could see them. Being transparent they practically disappear once imbedded in your skin. In most parts of your body, they merely become a nuisance, perhaps infecting or causing an irritating bump, until they may eventually work themselves out.

X-Ray showing fiber shard imbedded in finger.

Photo courtesy Brian Brandstetter, Mississauga Training Consultants, www.fiberoptictraining.com

Around your eye, however, they can be much more difficult to find and remove. The tears that wet your eyes make the transparent glass shards practically impossible to find and remove. The sharp ends of the fiber may cause it to imbed itself in the eye or surrounding tissue, making it even more difficult to remove. Unlike metallic particles, they cannot be removed with magnets,

It is imperative to follow procedures that minimize the dangers to the eye. Always wear protective eyewear with side shields, even if you normally wear glasses, to prevent any flying shards from getting near your eyes. Do not trust normal eyeglasses, since taking them off for a second allowed a fiber shard to land on my lower eyelash, where luckily, I found and removed it.

Be extremely careful whenever handling fibers, especially when stripping fiber or scribing and breaking fiber extending out of an adhesive connector. Instead of breaking it, scribe it gently, then slide your fingers up the connector ferrule, grasping the fiber and pulling it off. Then dispose of it carefully.

Most cleavers used for splicing or terminating prepolished/splice connectors hold the fiber after cleaving, so the only problem is disposing of it. We recommend using disposable containers like those used for soups at carry-out restaurants. Use it for all your fiber scraps and then seal it and dispose of it properly.

You can also set up your workplace to make it easier to avoid problems. Use a black plastic mat for a work surface. The dark background will make it easier to see the fibers you are working with and handle them more carefully. Any broken fibers that fall on the mat are easily found for disposal.

Some techs like to place a length of double stick tape or a loop of black electrical tape on the mat and stick fibers to the adhesive surface, then dispose of the tape when finished. I prefer to simply use a disposable container and place every fiber scrap into that container rather than leave them exposed on the work surface.

Other Considerations for Safety

Chemicals: Fiber optic splicing and termination use various chemical cleaners and adhesives as part of the processes. Normal handling procedures for these substances should be observed. Even simple isopropyl alcohol, used as a cleaner, is flammable and should be handled carefully. Manufacturers will supply "material safety data sheets" (MSDS) on request or they may be found on the Internet.

Splicing hazards: Fusion splicers use an electric arc to make splices, so care must be taken to insure no flammable gasses are present in the space where fusion splicing is done.

No Smoking: Smoking should also not be allowed around fiber optic work. The ashes from smoking contribute to the dirt problems with fibers, in addition to the possible presence of combustible substances (and, of course, the health risks.)

This is all very important � important enough to have a few workplace rules for all fiber optic techs that can prevent workplace accidents:

Fiber Optic Installation Safety Rules

(C)2024, The Fiber Optic Association, Inc.